Auto Back Wash Filter Housing Manufacturer

Auto Clean Filter Housing is also referred to as Self Cleaning Filter Housing.

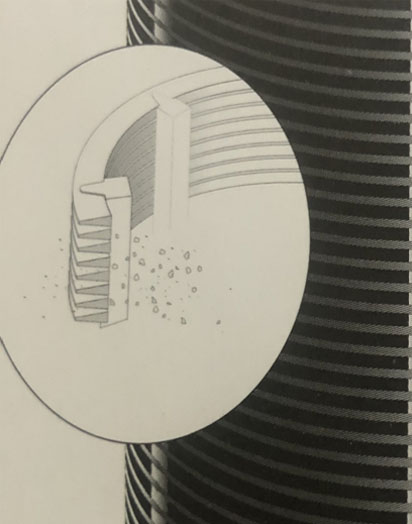

Auto clean filter or auto back wash filter generally made from Wedge wire element. It also called as Slot Tube. It is made up from a Triangle wire continues wrapped on a support tube, the gap between to wires act as a size of filtering media i.e. 35 micron and above. As on today’s technology the gap between two wire is possible maximum 35 micron. It means that the finest Wedge wire tube is available 35 micron and above. The wire is welded at each contact point on support rods. Hence the chances of changing the micron rating are very rare. It is very rigid construction.

As shown in the zoom, the upstream of the media is plain having given micron rating gaps. Hence the contamination will remain at upstream and the passed contamination will immediately pass from the remaining ‘V’ shape passage due to high velocity.

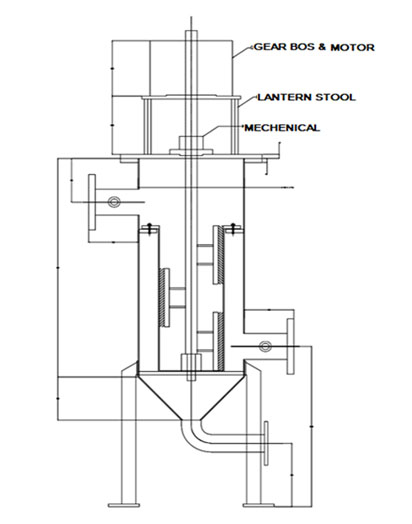

As shown in the drawing, Fluid will enter from nozzle –N1. And through Screen it will filter and filtered fluid will enter on outer side of screen-cylinder and will pass through Nozzle –N2 as a filtered fluid. Inner side of the screen, the contamination will accumulate. We provide Gear and motor operated Nylon wire-brush which rotate at 360º during the Back Wash mode to clean the Wedge wire screen.

When pressure drop reaches at set pressure, the Drain valve will open(N3), Motor will start and wire-brush will rotate. Due to this the flow will reduce to 33% at the outlet. But the filtration is on during the Back Wash operation and it will last for set time (1 to 3 minutes) as per the requirement and again the filter will go on operation mode. There is no need of standby filter since the flow is continue during backwash.